How to arrange an archival binding of a case? Packaging with storage media for an e-book Binding with a double wire loop “Wire-O”

The utility model relates to gift packaging for books in digital (electronic) form. The packaging consists of a hard cardboard cover. The cover is equipped with a magnetic latch; inside there is a rectangular case made of polymer material or pressed cardboard, with recesses for a miniCD-R disk, a USB flash drive and a microSD card, closed with a transparent cover. A soft foam mat is placed under the storage media, close to the transparent cover.

The utility model relates to gift packaging for books in digital (electronic) form.

The packaging for a disk and a paper book chosen by the applicant as a prototype is known from the document JP 2006123968, publ. 05/18/2001. This type of packaging is intended for joint storage by the user of paper and electronic versions of the book. The disc packaging is the same as a paper book box.

The known packaging, chosen by the applicant as a prototype, has a number of significant disadvantages. In particular, in modern world With rapidly developing digital technologies, paper books are fading into the background due to the lack of compactness and the inconvenience of their use in limited space, for example, in public transport, etc. At the same time, the known packaging does not allow, in addition to a CD, alternative storage media for the book to be stored in digital format, which, if it is impossible to use a paper book, eliminates the possibility of the user loading book information into a portable device that is not adapted for a CD.

The problem that the claimed utility model is aimed at solving is the creation of a device that expands the arsenal of technical means intended for joint storage of various options of information carriers related to a specific book, presented in digital format.

The technical result is to provide the possibility of creating a device that expands the arsenal of technical means intended for convenient joint storage of various options of information media related to a specific book presented in digital format.

The technical result is achieved by packaging with storage media for e-book, consisting of a hard rectangular cardboard cover, AND, ACCORDING TO THE DECLARED UTILITY MODEL, the cover is equipped with a magnetic latch, inside there is a rectangular case made of polymer material or pressed cardboard, with recesses for at least one miniCD-R disk, at least one USB flash drive and at least one microSD card, closed with a transparent cover, while a soft foam mat is placed under the storage media, close to the transparent cover.

Figures 1, 2 show the packaging, which appearance is a regular hardcover paper book. The packaging allows you to simultaneously accommodate a miniCD-R disk, a 2 mm thick USB flash drive and a microSD card.

The packaging consists of the following parts: a hard cardboard cover like a regular paper book (1), inside which there is a rectangular body (block) made of polymer material or pressed cardboard (2), with a recess (5) closed by a transparent lid (3), inside which storage media is located. The cover has a built-in magnetic latch (4) to prevent the book from opening when placed vertically.

The inner case with a shaped recess is a rectangular beam made of polymer material or pressed cardboard with a recess (5) for storing information media, made to the size of the transparent lid covering it. A soft foam mat is placed under the storage media/media, close to the transparent cover, to prevent them from moving inside the box.

The cover is a cut-out part from a sheet of transparent plastic glued to the internal block (6). The outer edge of the cover (7) and the cut in the plastic base (8) are made at an angle of 45° to fix the cover in the closed state. For ease of opening the lid, a groove (9) is made in the plastic base. The thickness of the plastic can be from 2 mm. up to 5 mm. The plastic must have the necessary flexibility so that the lid can bend slightly and the outer edge of the lid (7) can be inserted under the cut in the plastic base (8). Also, the plastic must be hard enough so that the lid does not open spontaneously.

When cutting out the cover, please note that the cuts of the side edges, as well as the semicircular cutout for opening the book, should be made vertical. The outer edge of the lid should be cut at an angle of 45° so that the cut indicated at the angle also acts as a locking factor for fixing the lid in the closed state. The inner edge of the lid should not be cut to the full thickness, but only half, from the underside of the plastic base, to create a more flexible hinge for convenient opening of the lid.

The packaging looks like a regular hardcover paper book - in this case it can be used as a gift option for packaging digital media.

The inner surface of the hard cover and the inner case with a figured recess can be supplemented with information about the contents of the book, illustrations, information about the author, publisher, etc.

If necessary, each carrier can have its own recess (niche) in the package. The recesses are located in a rectangular body (block) made of polymer material or pressed cardboard (not shown in the drawings).

A package containing information media for an e-book, consisting of a hard rectangular cardboard cover, characterized in that the cover is equipped with a magnetic latch; inside there is a rectangular case made of polymer material or pressed cardboard, with recesses for at least one miniCD-R disk, according to at least one USB flash drive and at least one microSD card, closed with a transparent cover, while a soft foam mat is placed under the storage media, close to the transparent cover.

In contact with

Classmates

From this article you will learn

- What types of hardcover are there?

- What types of softcover do printing houses offer?

- What types of binding are used when decorating books?

- Which company is best to order binding?

Binding is a collection of components of a printed publication, the function of which is to connect the pages into a single block, protect against external damage and create an artistically designed cover. The second meaning of this word is the action of creating a finished printed product (it would be more accurate to say “bookbinding”). There are many types of binding in printing. Which one to choose when designing a particular publication is decided depending on its type and purpose. In this article, we invite you to study the main types of binding and get acquainted with the areas of their application.

What types of hardcover are used in printing?

The ease of use of the printed product and its service life depend on the quality of the binding. In addition, the type of book binding is one of the factors determining the final cost of one copy of the publication. If you rely on reading comfort and durability, without taking into account high cost Without a doubt, the winners will be the hardcover types of books.

Binding 7BC (cellophaneized).

Making books with a type of binding such as 7BC involves using cardboard as a cover material, which is covered with a layer of polymer film. Its thickness is most often 32 microns, it can be either glossy or matte. The choice of one option or another is based on the designer’s intention, but it is worth considering that glossy lamination is cheaper. When creating this type of binding, offset and digital printing are used.

Type 7B binding in the production of book editions means the use of vinyl, leather, fabric, balacron, which is used to cover cardboard. It differs from 7BC in the use of embossing and embossing methods, that is, designs are applied using foil or extruded with a stamp.

One more looking firm The binding is integral, or Dutch. Its main difference from 7BC is the use of not two, but one sheet of cardboard covered with laminating film to make the cover. This method makes the production of publications faster and more economical, since there is no need to perform such labor-intensive procedures as gluing the margin and sides. Creasing is performed along the fold line to make the book easier to open. The thickness of the cover is determined by the type of cardboard and is selected individually for each publication. Other operations with this type of book binding are performed by analogy with hard binding.

The type of binding, which is called “French”, is characterized by the presence of a wide fabric or leather spine, as well as rounded corners. In the process of its creation, only manual labor is used; the block is sewn together with laces; this is a delicate work that requires a certain skill. Accordingly, this type of book binding costs more than others. Currently, it is used only for exclusive and gift editions.

An alternative type of binding is to connect the pages of the product using bolts. It is characterized by increased strength and long service life. Bolts are available in a wide range of colors, you can choose suitable option for any cover design. The length of the shortest bolt is 5 mm, and therefore the block that is being fastened cannot be less than 4 mm. If you lose sight of this point, the finished product will look unpresentable.

This type of binding is used in the production of photo albums. The block is protected at the top and bottom with cardboard sides, and the binding field is separated by a scoring line. There is another version of this type of binding - with solid strips along the width of the margin.

Winding on bolts allows you to design portfolios, presentations and reports in an original way. A stack of paper pages is encased in a cover made of cardboard or leatherette and secured with two or three bolts. This type of binding is appropriate when it is necessary to arrange a small number of copies of representative products, for example, catalogues. It is often preferred by customers when choosing types of binding for an album. It is also indispensable in the production of restaurant menus or price lists. This method of fastening makes it possible to replace individual pages with new ones without much difficulty. Metal and plastic bolts are used as fasteners.

Binding with double wire loop "Wire-O"

The leading role in creating this type of binding is played by wire formed into double loops. During the process of joining the pages, a special machine spreads the bottom edge of the loops and inserts them into blocks with pre-made holes, either round or square.

This type of binding is very popular among designers, although it has a significant drawback - it can only be used on products whose thickness does not exceed one inch. The pitch between the holes varies according to the thickness of the wire used.

A new type of binding that does not require either perforation of pages or the use of glue. A stack of paper with a cover is clamped using a metal “channel”, which allows you to instantly create a reliable and beautiful mount. In this case, it will not be possible to pull the sheet out from under the clamp.

If necessary, this type of binding can be used up to four times, opening and closing the “channel” again. The sheets of paper look just as perfect after it as they did before joining.

Premium photobook binding

When creating photo books, a special type of binding is used. It is characterized by double-page spreads - images of two adjacent pages are printed on one sheet. The spreads are creased, folded along the spine line, and then glued onto a cardboard or plastic base in a given sequence.

Modern materials make it possible to insert blocks with photographic images into binding covers of various designs and designs.

Soft bindings: economical solutions

In the process of making softcover books, the pages within the block are arranged either in notebooks or by collating. The result of the first option is an edition with a thread sewing inner block. In the second case, you get a book with an internal block on an adhesive seamless joint (CBS).

Soft bindings are the most common types of notebook bindings and types of magazine bindings.

When making a soft binding, the inner block is attached to the cover, which is printed on offset or coated paper, the density of which is not less than 160–300 g/m2. A thinner cover will not allow the book to survive more than two or three readings. The cover can be connected to the block in several basic ways.

KBS (adhesive seamless connection)

With this type of binding, the cover is glued to the book block. To make the adhesive joint stronger, torsioning is used - transverse cuts are created on the spine of the block, which are filled with adhesive during the joining process.

Stapling

This type of binding, such as binding with staples, is suitable for making brochures consisting of a small number of printed strips. For the cover, paper with a density of 160–250 g/m2 is selected. Then it is connected to the block with two or three metal brackets.

Sheets for this type of binding must first be prepared. They are folded, after which they are folded in accordance with the page numbering and secured with staples. For this, a wire stitching machine is used, which is not available in every printing shop or mini-printing shop. There may be several firmware options. The first is that the staples are installed along the fold line. This method is known as saddle stitch and is used when the book block contains no more than 128 pages. When the book is thicker, another option is used - stitching. The staples go right through the entire block along the edge of the foot.

A variation of saddle stitching can be called binding loop staples. In this case, a special stitching head is used. During the joining process, a loop is formed on the outside of the spine. It serves to hold the book in a removable cover (a regular folder with three split rings). There is no need to drill any holes in the book block.

When considering soft options for connecting pages, one cannot help but mention the most common types of bindings for documents:

The oldest type of binding, which allows you to systematize various working documents, is their stitching, or lacing. It allows you to ensure the safety of all papers, eliminating the possibility of their replacement or unauthorized removal. Today, documents are stitched using threads and thermal cords, which are sealed for additional protection.

This type of binding is typical for creating all possible types of calendars, presentations and reports, as well as reports and abstracts. Documents containing accounting data are also bookleted.

Based on the materials used, there are several stitching options:

- Binding with a plastic spring is an inexpensive way to store documents in a single folder. Allows you to create large volumes. It is used when working with project documentation, for internal accounting needs, and when preparing reports. Paper sheets are stacked, plastic covers are added and connected using a special device;

- Binding with a metal spring guarantees a more reliable connection and is distinguished by the fact that when using it, pages can be rotated 360°. This binder is used for binding working documents or brochures.

Recent achievements include the following type of binding. Heat treatment protects documents, giving them a pleasant appearance. This method of connecting individual pages into a single whole is used when preparing coursework and dissertations, dissertations, catalogs, and manuals. There are several options for thermal binding:

- hard - most common when creating albums, binding manuscripts and other documents for which it is important to ensure preservation in their original form;

- soft – widely used for the design of advertising materials and presentations.

What types of book binding are there?

Hard book binding guarantees long-term preservation of the publication and is distinguished by its aesthetic appearance. The concept of binding includes not only a cardboard cover, but also other elements without which its creation is not complete - endpapers, captals, gauze flaps.

Flyleaf is a sheet of thick paper, most often offset, the density of which is 100–180 g/m2. It is bent in half and glued with one half to the side, and the other to the first or last page of the publication. To give the endpaper time to dry as best as possible, the first and last notebooks of a book block are often printed first.

Left behind- this is a narrow strip of paper (for a round spine) or cardboard (for a straight spine).

A necessary binding element is drip- a narrow strip of fabric with a widened edge that peeks out from under the covering at the top and bottom of the cover. The most common type in bookbinding is white captal, but you can often see the use of colored braid for design purposes.

In reproduction albums, art books and some other publications they are sometimes used lasse– a bookmark in the form of a very narrow ribbon, fixed under the captal. The lasse is glued exclusively by hand, so the price of products with such a tab is invariably higher.

To keep the notebooks of the block more securely, use an auxiliary element such as printing gauze. It or spunbond, a polymer non-woven material, is used to cover the spine.

Types of hardcover used in printing production are described in GOST 22240–76 “Binding covers and lids. Classification":

No. 5 – composite binding cover: first, the sides are covered with one type of material, and then, with a gap, they are connected to another, made of fabric. The complexity of creating such a cover makes its use not very popular; it can be seen, for example, on art publications produced using manual labor. This makes this type of binding similar to options 8 and 9.

No. 6 – one-piece cover made from thick cardboard. Professionals call this type of binding integral or Dutch. IN last years it is often used in educational publications. The cardboard used for lids is thinner than what is usually used for bookbinding. This reduces the cost of the product and reduces its weight, which is important for students who carry textbooks with them.

No. 7 – one-piece binding cover, is by far the most common type of binding. These are cardboard sides and back, which are connected by some material - coated paper, vinyl, calico, lederin, leather, flock or fabric.

This type of binding is simple and inexpensive, and, therefore, is used when preparing coursework, diplomas and dissertations. By using the newly introduced channel binding technology, giving an attractive appearance diploma work takes a few minutes.

No. 8 – binding cover with overlay sides and overlay spine. Each side and spine are covered with material separately. On the sides it is folded on four sides, on the spine - on two sides, at the top and bottom.

No. 9 – composite cover with edged spine. The spine and sides are covered various materials, while the spine is equipped with a border.

In contact with

The production of photo books with this type of cover has also been established. The use of multi-color prints with subsequent pressing of a transparent polymer film significantly increases the visual capabilities of binding covers. In this version, this binding was called 7BC binding (type 7 cover with paper cellophane covering material), and the photo book designed in this way was called -.

The calculations of parameters given below should be considered theoretical. The final dimensions are obtained immediately after, taking into account the specifics of the assembly process. Depending on the thickness of the photo book block, cover paper with a density of 80 to 200 is used. g/m2, while paper with a surface density of up to 140 g/m2 recommended for use with block thickness up to 10 mm, density up to 180 g/m2- for block thicknesses up to 15 mm, and paper of higher surface density - for thicker blocks. You can use offset and coated paper.

In type 7 binding covers, the cardboard sides are covered with a covering material, so gray binding cardboard with a thickness of 1.25 to 3.00 mm is used for their production. It is recommended to use binding board with split cutting, when the machine direction is along the spine of the book, thereby reducing the risk of warping of the binding cover. Lids with a straight spine must have a hard or semi-hard edge. Hard backing is made from binding cardboard used for the sides of the binding cover, or 20-30% thinner than it.

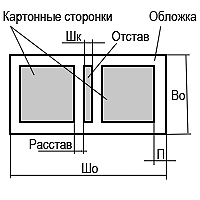

The size of the blanks for the parts of the binding cover is determined by calculation, based on the dimensions of the parts being manufactured, the sizes of the edges and the laws that allow us to determine the width of the parts, spaces and the finished cover with a straight spine shape. The blanks for the cardboard sides of binding covers type 7 (hard photo cover), in relation to the dimensions of the trimmed photo book block, should be larger in width by the width of the front edges and smaller by the width of the spacers, and in height - larger by the width of the upper and lower edges. The diagram shows: Wb, Wb - width and height of the block; Shs, Vs - width and height of the sides; p - separation; Kv, Kn - upper and lower edges; Kp - front edge.

Edges are parts of the binding cover protruding several millimeters beyond the edges of the book block, intended to ventilate the book during storage and to protect the edges of the book block. The size of the edges is 2mm for small books, 3mm for medium ones, and 4mm for large ones. In our workshop we take all edges the same and equal to 3 mm. regardless of the size of the photo book (Kv=Kn=Kp=K=3mm.)

The gap is the distance between the cardboard side of the binding cover and the gap, equal to approximately 5 mm. plus the thickness of the cardboard for the sides and back. When making a lid on a lid-making machine, the spacing is set by a foot gauge. For example: on the Bulros 100K machine the presser foot width is 8.5 mm. (p=8.5mm.) Sho, Vo - width and height of the cover photo (covering material); P - bend allowances equal to 30mm. on all sides; Шк - spine width, depending on the number of turns in the block (Np.). After calculating the cardboard parts, it remains to calculate the dimensions of the covering material for the one-piece binding cover. In our case, these are the dimensions of a paper sheet with a photograph intended for a hard photo cover. Taking bend allowances equal to 30 mm, we calculate the dimensions of the photo image on the cover using formulas that take into account production experience and some regularities in assembling the cover. Attention! When laying out the layout of a photo cover, it is necessary to place the image over the entire area, including the folding margins, while important design elements (inscriptions, people’s faces) must be at least 40mm apart. from the edge of the cover layout. It is unacceptable to place any frames along the edges of the layout.

We will summarize the final values of the parameters of the parts of the binding cover for the hard photo cover in the table. The last column of the table shows an example of calculating the details of a binding cover for a 15-page spread photo book measuring 20x20.

Calculation of the dimensions of the parts of a one-piece binding cover

| Size name | Size designation | Calculation formula | Value (mm.) | Example (mm.) |

|---|---|---|---|---|

| Block height | Wb | measured per finished block | - | 193 |

| Block width | Shb | measured per finished block | - | 193 |

| Block thickness | TB | measured per finished block | - | 20 |

| Kant | TO | - | 3 | 3 |

| Breakup | R | - | 8,5 | 8,5 |

| Width of cardboard side | Shs | Shs = Shb + K - R | - | 187,5 |

| Height of cardboard side | Sun | Sun = Wb +2K | - | 199 |

| Cardboard side thickness | Ts | - | 2 | 2 |

| Bed/Spine Width | Shk | Shk = Tb | - | 20 |

| Bed/Spine Height | VC | Vk = Sun | - | 199 |

| Bend allowance | P | - | 30 | 30 |

| Photo cover height | In | Vo = Sun + 2P | - | 259 |

| Photo cover width | Shaw | Sho = 2Shs + 2P + Shk +2Ts + 2P | - | 476 |

Hardcover is usually done by printing houses. But if you want to master the basics of this business without spending much money, then we will tell you how you can weave a beautiful hard crust at home. It is worth considering that the quality of homemade binding may differ slightly from professionally performed work using special equipment.

Materials:

- 32 A4 sheets (or tracing paper)

- PVA glue and hot glue gun, if available at home

- Hard cardboard (can be corrugated)

- A piece of fabric (any type will do) or leather

- Stapler

- Rubber band (or large paper clip)

Step 1: Ream of Paper

We have to make 4 solid pages, each of which consists of 8 sheets.

Distribute the sheets into separate piles.

Step 2: Fold

Carefully fold each stack in half as shown in the photo.

Step 3: U-Turn

Unfold all the stacks and turn them over to the reverse side.

Step 4: Paperclips

It is best to use a stapler with a long arm. It allows you to staple an 8-page stack at a time without any extra steps.

If you do not have such a stapler at hand, then using a standard model, fasten the pages from the top and from the inside.

Step 5: Gluing

Cut a piece of fabric to the height of the sheet. The thickness of the fabric should be 5 times thicker than the stack itself.

Use a large paper clip or rubber band to hold the sheets in a static position (see Figure 2).

Apply glue along the side of the package so that it does not get inside, between the pages (Fig. 2).

Before the glue dries, attach the prepared piece of fabric to the side.

Step 6: Trimming

You can skip this step if you are happy with the size of the book.

You need to cut the sheets carefully along a ruler with a sharp knife or scalpel.

Step 7: Marker

Place the paper stack on the cardboard. Mark the contours with a marker, moving the border along 3 edges by 5 mm (see Fig. 1).

Cut out the cardboard and make several copies according to its dimensions.

Step 8: Side

Prepare a separate cardboard rectangle for the end of the book according to your dimensions.

Step 9: Fabric

Place all the cardboard parts for the book on the prepared piece of fabric. Mark the border (25 mm from the edge) and cut the material.

Step 10: Connection

Apply white glue to the cardboard and place it on the fabric as shown in the picture. There should be an equidistant space from the end cardboard between the 2 crusts.

Step 11: Edges

Apply glue to the bottom edges of the fabric and attach them to the cardboard. Similarly, do the same with the sides.

Step 12: Pages

Glue 2 white strips (preferably made of cotton paper) in the middle and pour glue on them.

Place a stack of paper in the center. It should not stick to the end cardboard - only to the 2 strips. You'll need something to hold the stack upright while the glue dries.

Step 13: Backing

The hardcover is actually ready. But if you want to give a realistic look to the book, then it is better to make a pattern for the covers using the “marble paper” method (you can buy it in special stores) or create your own backing.

Here (paperpaper.ru/handmade-business/) I read a story about how a student, unable to find a suitable notebook in a bookstore (he wanted a notebook with blank, unlined sheets), decided to produce it himself, on his knee.

Today, he and his friend make approximately 1,500 notebooks per month and have a revenue of 150 thousand rubles per month.

They did not require large investments or funds for promotion. Production developed gradually, promoted through local exhibitions for handicrafts.

These notebooks are sold both in local stores and online (for example, through this online store - beautydecay.ru/items?i=588).

This example gives the green light to the creation of entirely new notepads (or notebooks) that current printing businesses are reluctant to produce.

For example, I haven’t found notebooks without margins on sale for a long time (these margins only narrow down the space for me). Previously, only these were sold (and schoolchildren drew the fields themselves using a ruler). Today, all enterprises have adjusted to mass demand and such notebooks cannot be found.

Previously, by the way, sketch pads were sold. They contained gray paper, were very cheap, had a hard cardboard cover (to make it easier to draw on the go) and a convenient perforated strip for tearing off sheets. Now I can’t find such notebooks even in specialized stores for artists.

Another option. I write down all the passwords for various Internet services and sites in a notebook. Previously, I used a regular notebook, but now that I have accumulated several dozen sites, it has become very inconvenient to search through such records.

I found a solution (and I searched for it for a very long time) - I bought a notebook with colored stripes in the margins, and on these strips I wrote out letters English alphabet to divide the entire notepad into letter zones. And in these letter zones I write down domains and passwords for them (this notebook is inconvenient because it has a too thick cover and too wide sheets - taking one on the road is not very convenient; and I have to take it with me when I go to other cities with laptop).

The most the best option Such a notebook would be like a compact telephone directory with Latin letters in bookmarks - but I still haven’t found one like that on sale.

Something like this:

Also, I still haven’t found a suitable diary for myself. All current diaries are designed for businessmen who work in real life (going to meetings, going to restaurants, actively using the phone). There are practically no daily planners for work-at-home moms (like me), who rarely leave the house, but still manage to do a lot of daily tasks (which have virtually nowhere to write down).

You can also make a separate notebook for upcoming purchases (I make a shopping list over the course of a day or even two days - you can’t remember everything at once, I remember and write down as I go). Of course, for this purpose you can use both tear-off paper for notes and ordinary notebooks, but: ordinary notebooks are usually narrow and awkwardly lined (I would like to have separate columns for the name of the product, its quantity and the “bought/not bought” mark); and you have to throw away the tear-off paper after use (and sometimes it’s useful to look at old notes so that, for example, you don’t forget to buy something today that you didn’t find in the store yesterday). Such a notebook should not be too thick (so as not to carry excess paper to the store) and must have a spring (so that pages that have become unnecessary can be torn out painlessly at any time).

And it’s not at all necessary to make such notebooks on your knees - after all, there are a lot of idle printing houses.

By the way, the fundamentally clean notebooks of the above-mentioned student gave me the idea of publishing template business cards (that is, almost empty ones, into which you can manually enter the name of the company, type of activity and telephone number).

These are approximately the same business cards (only, of course, I would line them, although you can sell them blank ones).

Beginning entrepreneurs do not necessarily need to order a hundred personalized business cards from an advertising agency (this will be too expensive and it is not a fact that all these business cards will be useful). It’s enough to buy a dozen blank business cards in some bookstore and write whatever you want on them. Fast, cheap and flexible (you never know, you’ll have to change your type of activity or phone number, so you won’t have to throw out filled out business cards that have suddenly become unnecessary).

If you sit and think about the rapidly changing conditions of our lives and activities, you can come up with many more new types of printed products that will be in demand by a variety of people (and not the one-faced thoughtless crowd, according to modern printing enterprises, who don’t care where, on what or how to write).

Let this notebook, designed specifically for T-shirt designers, be one of your inspirations: