Charging circuits for car batteries using thyristors. Basic thyristor charger. These are normal voltages at the pins of the CD4538 chip

The device with electronic control of the charging current is made on the basis of a thyristor phase-pulse power regulator. It does not contain scarce parts, and if the elements are known to be good, it does not require adjustment.

The charger allows you to charge car batteries with a current from 0 to 10 A, and can also serve as a regulated power source for a powerful low-voltage soldering iron, vulcanizer, or portable lamp. The charging current is similar in shape to pulse current, which is believed to help extend battery life. The device is operational at temperatures environment from - 35 °C to + 35 °C.

The device diagram is shown in Fig. 2.60.

The charger is a thyristor power regulator with phase-pulse control, powered from winding II of the step-down transformer T1 through the moctVDI + VD4 diode.

The thyristor control unit is made on an analogue of the unijunction transistor VT1, VT2. The time during which capacitor C2 is charged before switching the unijunction transistor can be adjusted with a variable resistor R1. When the engine is in the extreme right position according to the diagram, the charging current will be maximum, and vice versa.

Diode VD5 protects the control circuit of thyristor VS1 from reverse voltage that occurs when the thyristor is turned on.

The charger can later be supplemented with various automatic components (switching off at the end of charging, maintaining normal battery voltage during long-term storage, signaling the correct polarity of the battery connection, protection against output short circuits, etc.).

The disadvantages of the device include fluctuations in the charging current when the voltage of the electric lighting network is unstable.

Like all similar thyristor phase-pulse regulators, the device interferes with radio reception. To combat them, you should provide an LC network filter, similar to that used in switching network power supplies.

Capacitor C2 - K73-11, with a capacity of 0.47 to 1 µF, or. K73-16, K73-17, K42U-2, MBGP.

We will replace the KT361A transistor with KT361B - KT361Ё, KT3107L, KT502V, KT502G, KT501Zh - KT50IK, and KT315L - with KT315B + KT315D KT312B, KT3102L, KT503V + KT503G, P307 Instead of KD10 5B suitable diodes KD105V, KD105G or. D226 with any letter index.

Variable resistor R1 - SP-1, SPZ-30a or SPO-1.

Ammeter PA1 - any direct current with a scale of 10 A. It can be made independently from any milliammeter by selecting a shunt based on a standard ammeter.

Fuse F1 is a fuse, but it is convenient to use a 10 A circuit breaker or a car bimetallic fuse for the same current.

Diodes VD1 + VP4 can be any for a forward current of 10 A and a reverse voltage of at least 50 V (series D242, D243, D245, KD203, KD210, KD213).

The rectifier diodes and thyristor are installed on heat sinks, each with a useful area of about 100 cm2. To improve the thermal contact of devices with heat sinks, it is advisable to use thermally conductive pastes.

Instead of a thyristor. KU202V will fit KU202G - KU202E; It has been verified in practice that the device works normally with more powerful thyristors T-160, T-250.

It should be noted that it is permissible to use the metal casing wall directly as a heat sink for the thyristor. Then, however, there will be a negative terminal of the device on the case, which is generally undesirable due to the danger of accidental short circuits of the positive output wire to the case. If you mount the thyristor through a mica gasket, there will be no danger of a short circuit, but the heat transfer from it will worsen.

The device can use a ready-made network step-down transformer of the required power with a secondary winding voltage of 18 to 22 V.

If the transformer has a voltage on the secondary winding of more than 18 V, resistor R5 should be replaced with another one of higher resistance (for example, at 24...26 V, the resistor resistance should be increased to 200 Ohms).

In the case when the secondary winding of the transformer is tapped from the middle, or there are two identical windings and the voltage of each is within the specified limits, then it is better to make the rectifier according to a standard full-wave circuit using two diodes.

When the secondary winding voltage is 28...36 V, you can completely abandon the rectifier - its role will simultaneously be played by the thyristor VS1 (rectification is half-wave). For this version of the power supply, it is necessary to connect a separating diode KD105B or D226 with any letter index (cathode to resistor R5) between resistor R5 and the positive wire. The choice of thyristor in such a circuit will be limited - only those that allow operation under reverse voltage (for example, KU202E) are suitable.

For the described device, a unified transformer TN-61 is suitable. Its three secondary windings must be connected in series, and they are capable of delivering current up to 8 A.

All parts of the device, except for transformer T1, rectifier diodes VD1 - VD4, variable resistor R1, fuse FU1 and thyristor VS1, are mounted on a printed circuit board made of foil fiberglass 1.5 mm thick.

See other articles section.

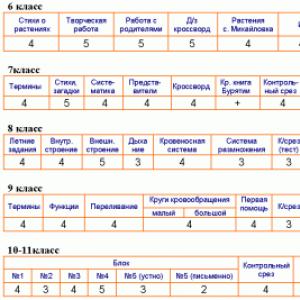

It is known that during the operation of batteries, their plates can become sulfated, which leads to battery failure. If you charge with a pulsed asymmetric current, then it is possible to restore such batteries and extend their service life, while the charge and discharge currents should be set to 10: 1. Made by me Charger, which can operate in 2 modes. The first mode provides normal charging of batteries with a direct current of up to 10 A. The amount of charging current is set by thyristor regulators. The second mode (Vk 1 is off, Vk 2 is on) provides a pulsed charge current of 5A and a discharge current of 0.5A.Let's consider the operation of the circuit (Fig. 1) in the first mode. An alternating voltage of 220 V is supplied to the step-down transformer Tr1. In the secondary winding, two voltages of 24 V are generated relative to the midpoint. We managed to find a transformer with a midpoint in the secondary winding, which makes it possible to reduce the number of diodes in the rectifiers, create a power reserve and ease the thermal regime. The alternating voltage from the secondary winding of the transformer is supplied to a rectifier using diodes D6, D7. The plus from the middle point of the transformer goes to resistor R8, which limits the current of the zener diode D1. Zener diode D1 determines the operating voltage of the circuit. A thyristor control generator is assembled on transistors T1 and T2. Capacitor C1 is infected through the circuit: power supply plus, variable resistor R3, R1, C1, minus. The charging rate of capacitor C1 is controlled by variable resistor R3. Capacitor C1 is discharged along the circuit: emitter - collector T1, base - emitter T2, R4 capacitor mine. Transistors T1 and T2 open and a positive pulse from the emitter T2 through the limiting resistor R7 and decoupling diodes D4 - D5 arrives at the control electrodes of the thyristors. In this case, switch Vk 1 is turned on, Vk 2 is turned off. The thyristors, depending on the minus phase of the alternating voltage, open one by one, and the minus of each half-cycle goes to the minus of the battery. Plus from the midpoint of the transformer through the ammeter to the plus of the battery. Resistors R5 and R6 determine the operating mode of transistors T1-2. R4 is the load of the T2 emitter on which a positive control pulse is released. R2 - for more stable operation of the circuit (in some cases it can be neglected).

Operation of the memory circuit in the second mode (Vk1 – off; Vk2 – on). When Vk1 is turned off, the control circuit of thyristor D3 is interrupted, while it remains permanently closed. One thyristor D2 remains in operation, which rectifies only one half-cycle and produces a charge pulse during one half-cycle. During the idle second half-cycle, the battery is discharged through the switched on Vk2. The load is an incandescent light bulb 24V x 24 W or 26V x 24 W (when the voltage on it is 12V, it consumes a current of 0.5 A). The light bulb is placed outside the housing so as not to heat the structure. The charging current value is set by regulator R3 using an ammeter. Considering that when charging the battery, part of the current flows through load L1 (10%). Then the ammeter reading should correspond to 1.8A (for a pulse charging current of 5A). since the ammeter has an inertia and shows the average value of the current over a period of time, and the charge is made during half the period.

Details and design of the charger. Any transformer with a power of at least 150 W and a voltage in the secondary winding of 22 - 25 V is suitable. If you use a transformer without a midpoint in the secondary winding, then all elements of the second half-cycle must be excluded from the circuit. (Bk1, D5, D3). The circuit will be fully operational in both modes, only in the first it will work on one half-cycle. Thyristors can be used KU202 for a voltage of at least 60V. They can be installed on a radiator without isolation from each other. Any D4-7 diodes for an operating voltage of at least 60V. Transistors can be replaced with germanium low-frequency transistors with appropriate conductivity. works on any pairs of transistors: P40 – P9; MP39 – MP38; KT814 – KT815, etc. Zener diode D1 is any 12–14V. You can connect two in series to set the desired voltage. As an ammeter, I used the head of a 10 mA, 10 division miliammeter. The shunt was selected experimentally, wound with 1.2 mm wire without a frame to a diameter of 8 mm, 36 turns.

Setting up the charger. If assembled correctly, it works immediately. Sometimes it is necessary to set the Min - Max regulation limits. selection of C1, usually in the direction of increase. If there are regulation failures, select R3. Usually I connected a powerful light bulb from an overhead projector 24V x 300W as a load for adjustment. It is advisable to install a 10A fuse in the open circuit of the battery charge.

Discuss the article BATTERY CHARGER

The figure shows a diagram of a thyristor charger, which automatically stops charging a car battery when the battery is fully charged.

Operating principle: the 220V mains voltage arriving at T1 is reduced and supplied to the rectifier diodes D1 D2, then the 12V voltage is supplied in two ways through D3R1R2 and the high power thyristor D4. Through the first circuit, the battery is charged with a current of only 0.1A. The value of this current is close to the self-discharge value of the battery, so even a long charge of the battery will not harm it and will always maintain it in full readiness. The current is set by resistor R2.

The second charging circuit goes through thyristor D4; a current of up to 6A can flow through it. The thyristor is controlled using a zener diode D6 (8V), a thyristor D7 and a voltage divider on R5R6, the middle point of which is connected through a diode D5 to the control electrode D4. The level of termination of charging with a large current is set using a voltage divider on R3 and variable R4. The constant voltage is removed from the R4 engine and controls the switching on and off of the thyristor D7 through the zener diode D6.

The threshold voltage at which the battery is fully charged and the charging current must be significantly reduced is set using resistor R4 individually for each battery.

When manufacturing a charger, a 100V transformer is required, the secondary winding of which must be designed for a voltage of 45V with a tap from the middle. If you don’t have the required transformer, you can take a power transformer from an old TV, leaving the primary winding unchanged, and wind the secondary winding at 45V. The number of turns should be as follows: the number of turns for heating the cathode of the kinescope multiplied by 7. The winding must be made of PEL, PEV-1, PEV-2 wire with a diameter of 2 mm.

Literature MRB 1018

- Similar articles

Login using:

Random articles

- 20.09.2014

General information about electrical wiring Electrical wiring is a collection of wires and cables with their associated fastenings, supporting and protective structures. Hidden electrical wiring has a number of advantages over open wiring: it is safer and more durable, protected from mechanical damage, hygienic, and does not clutter walls and ceilings. But it is more expensive and more difficult to replace if necessary. ...

- 27.09.2014

Based on the K174UN7, you can assemble a simple generator with 3 sub-ranges: 20...200, 200...2000 and 2000...20000Hz. The PIC determines the frequency of the generated oscillations; it is built on elements R1-R4 and C1-C6. The negative feedback circuit, which reduces nonlinear distortions of the signal and stabilizes its amplitude, is formed by resistor R6 and incandescent lamp H1. With the indicated circuit ratings...

The use of thyristor chargers is justified - restoration of battery functionality occurs much faster and more “correctly”. The optimal value of the charging current and voltage is maintained, so it is unlikely to harm the battery. After all, overvoltage can cause the electrolyte to boil away and destroy the lead plates. And all this leads to failure. But you need to remember that modern lead batteries can withstand no more than 60 full discharge and charge cycles.

General description of the charger circuit

Anyone can make thyristors if they have knowledge of electrical engineering. But to do all the work correctly, you need to have at least the simplest measuring device- multimeter.

It allows you to measure voltage, current, resistance, and check the performance of transistors. And there are the following functional blocks:

- The reduction device is in the very simple case This is a regular transformer.

- The rectifier block consists of one, two or four semiconductor diodes. A bridge circuit is usually used because it produces almost pure direct current without ripple.

- A filter bank is one or more electrolytic capacitors. With their help, the entire alternating component in the output current is cut off.

- Voltage stabilization is carried out using special semiconductor elements- zener diodes.

- An ammeter and a voltmeter monitor current and voltage, respectively.

- The output current parameters are adjusted by a device assembled using transistors, a thyristor and a variable resistance.

The main element is a transformer

There’s simply no way without it; it’s impossible to make a thyristor-controlled charger without using a transformer. The purpose of using a transformer is to reduce the voltage from 220 V to 18-20 V. This is exactly what is needed for normal operation of the charger. General design of the transformer:

- Magnetic core made of steel plates.

- The primary winding is connected to the source alternating current 220 V.

- The secondary winding is connected to the main board of the charger.

Some designs may use two secondary windings connected in series. But in the design discussed in the article, a transformer is used, which has one primary and the same number of secondary windings.

Rough calculation of transformer windings

It is advisable to use a transformer with an existing primary winding in the design of a thyristor charger. But if there is no primary winding, you need to calculate it. To do this, it is enough to know the power of the device and the cross-sectional area of the magnetic circuit. It is advisable to use transformers with a power of over 50 W. If you know the cross-section of the magnetic circuit S (sq. cm), you can calculate the number of turns for every 1 V of voltage:

N = 50 / S (sq. cm).

To calculate the number of turns in primary winding, you need to multiply 220 by N. The secondary winding is calculated in a similar way. But you need to take into account that in a household network the voltage can jump up to 250 V, so the transformer must withstand such changes.

Winding and assembly of the transformer

Before you start winding, you need to calculate the diameter of the wire that you will need to use. To do this you need to use a simple formula:

d = 0.02×√I (windings).

The wire cross-section is measured in millimeters, the winding current is measured in milliamps. If you need to charge with a current of 6 A, then substitute the value of 6000 mA under the root.

Having calculated all the parameters of the transformer, you begin winding. Lay the coil evenly to the coil so that the winding fits in the window. Fix the beginning and end - it is advisable to solder them to free contacts (if any). Once the winding is ready, you can assemble the transformer steel plates. Be sure to coat the wires with varnish after winding is completed, this will help get rid of the humming noise during operation. The core plates can also be treated with an adhesive solution after assembly.

PCB manufacturing

To make your own printed circuit board on a thyristor, you need to have the following materials and tools:

- Acid for cleaning the surface of foil material.

- Solder and tin.

- Foil textolite (getinax is more difficult to obtain).

- Small drill and drill bits 1-1.5 mm.

- Ferric chloride. It is much better to use this reagent, since with its help excess copper is removed much faster.

- Marker.

- Laser printer.

- Iron.

Before starting installation, you need to draw the tracks. It is best to do this on a computer, then print the drawing on a printer (necessarily laser).

Printing should be done on a sheet from any glossy magazine. The drawing is translated very simply - the sheet is heated with a hot iron (without fanaticism) for several minutes, then it cools down for a while. But you can also draw paths by hand with a marker, and then place the PCB in the solution for a few minutes.

Purpose of memory elements

The device is based on a phase-pulse regulator on a thyristor. There are no scarce components in it, so if you install serviceable parts, the entire circuit will be able to work without adjustment. The design contains the following elements:

- Diodes VD1-VD4 are a bridge rectifier. They are designed to convert alternating current into direct current.

- The control unit is assembled on unijunction transistors VT1 and VT2.

- The charging time of capacitor C2 can be adjusted by variable resistance R1. If its rotor is shifted to the extreme right position, the charging current will be highest.

- VD5 is a diode designed to protect the thyristor control circuit from reverse voltage that occurs when turned on.

Such a scheme has one big drawback- large fluctuations in the charging current if the network voltage is unstable. But this is not a hindrance if a voltage stabilizer is used in the house. You can assemble a charger using two thyristors - it will be more stable, but it will be more difficult to implement this design.

Installation of elements on a printed circuit board

It is advisable to mount the diodes and thyristor on separate radiators, and be sure to isolate them from the housing. All other elements are installed on the printed circuit board.

It is undesirable to use wall-mounted installation - it looks too unsightly and is dangerous. To place elements on the board, you need:

- Drill holes for the legs with a thin drill.

- Tin all printed tracks.

- Cover the tracks with a thin layer of tin, this will ensure reliable installation.

- Install all elements and solder them.

After installation is complete, you can coat the tracks with epoxy resin or varnish. But before that, be sure to connect the transformer and the wires that go to the battery.

Final assembly of the device

After installing the charger on the KU202N thyristor, you need to find a suitable housing for it. If there is nothing suitable, make it yourself. You can use thin metal or even plywood. Place the transformer and radiators with diodes and thyristor in a convenient place. They need to be well cooled. For this purpose, you can install a cooler in the rear wall.

You can even install a circuit breaker instead of a fuse (if the dimensions of the device allow). On the front panel you need to place an ammeter and a variable resistor. Having assembled all the elements, you begin testing the device and its operation.