DVD drive device structure. How CD and DVD discs are structured. If the player does not turn on

CD-ROM drive device.

A CD-ROM drive is a complex electronic-optical-mechanical device for reading information from laser disks. A typical drive consists of an electronics board (sometimes two or even three boards - a spindle control circuit and an opto-receiver amplifier separately), a spindle assembly, an optical read head with a drive for its movement and disk loading mechanics.

The electronics board contains:

- circuit for amplification and correction of the signal from the optical head;

- PLL signal circuits and spindle ACS;

- Reed-Solomon code processor;

- ACS schemes for beam focusing and dynamic track tracking;

- control circuit for moving the optical head;

- control processor (logic);

- buffer memory;

- interface with controller (IDE/SCSI/others);

- interface and output connectors sound signal;

- block of mode switches (jumpers/jumpers).

A typical drive consists of an electronics board, a spindle motor, an optical read head system and a disk loading system. The electronics board contains all the drive control circuits, the interface with the computer controller, the interface connectors and the audio signal output. Most drives use one electronics board, but in some models separate circuits are placed on small auxiliary boards.

Spindle assembly (the motor and the spindle itself with the disk holder) are used to rotate the disk. Typically the disk rotates at a constant linear speed, which means that the spindle changes speed depending on the radius of the track from which the optical head is currently reading information. As the head moves from the outer radius of the disk to the inner radius, the disk must quickly increase its rotational speed by approximately doubling, so good dynamic response is required from the spindle motor. The motor is used for both acceleration and deceleration of the disk.

The spindle itself is fixed to the axis of the spindle motor (or in its own bearings), to which the disk is pressed after loading. The surface of the spindle is sometimes covered with rubber or soft plastic to prevent the disc from slipping, although in more advanced designs only the upper clamp is rubberized to increase the accuracy of the disc being installed on the spindle. The disk is pressed against the spindle using the upper clamp located on the other side of the disk. In some designs, the spindle and clamp contain permanent magnets, the attractive force of which forces the clamp through the disk to the spindle. Other designs use coil or flat springs for this purpose.

Optical head system consists of the head itself and its movement system. The head contains a laser emitter based on an infrared laser LED, a focusing system, a photodetector and a pre-amplifier. Focusing system It is a movable lens driven by an electromagnetic voice coil system, similar to the movable loudspeaker system. Change in tension magnetic field cause the lens to move and refocus the laser beam. Thanks to its low inertia, such a system effectively tracks the vertical runout of the disk even at significant rotation speeds.

Head movement system has its own drive motor, which drives the carriage with the optical head using a gear or worm gear. To eliminate backlash, a connection with an initial voltage is used: with a worm gear - spring-loaded balls, with a gear - pairs of gears spring-loaded in opposite directions. The motor used is usually a stepper motor, and much less often a brushed DC motor.

Disc loading system There are three options: using a special cassette for the disk (caddy), inserted into the receiving niche of the drive (similar to how a 3" floppy disk is inserted into the drive), using a retractable tray (tray), on which the disk itself is placed, and using a retractable mechanism. Systems with Tray usually contain a special motor that allows the tray to extend, although there are designs (for example, Sony CDU31) without a special drive that are pushed in by hand. Systems with a retracting mechanism are usually used in compact CD-Changers for 4-5 discs, and necessarily contain a motor for drawing in and ejecting disks through a narrow charging slot.

On the front panel The drive usually contains an Eject button for loading/unloading a disc, a drive access indicator, and a headphone jack with an electronic or mechanical volume control. A number of models have added a Play/Next button to start playing audio discs and switch between audio tracks.

Most drives also have a small hole on the front panel for emergency removal of the drive in cases where in the usual way this cannot be done - for example, if the tray drive or the entire CD-ROM fails, if there is a power failure, etc. You usually need to insert a pin or a straightened paper clip into the hole and gently press - this unlocks the tray or disk case, and it can be pulled out manually (although there are drives, for example Hitachi, in which you need to insert a small screwdriver into such a hole and rotate it located behind the front drive panel axle with slot).

CD-ROM block diagram

Functional diagram of CD-ROM

A very important component of the device is the optical-electronic information reading system. Despite its small size, this system is a very complex and precise optical device.

It consists of:

- servo disk rotation control systems;

- Servo positioning systems for laser reading devices;

- servo autofocus systems; radial tracking servo system;

- reading systems;

- laser diode control circuits.

The servo disk rotation control system ensures the constant linear speed of the reading track on the disk relative to the laser spot. In this case, the angular speed of disk rotation depends both on the distance of the reading head to the center of the disk, and on the conditions for reading information.

The servo system for positioning the information reading head ensures a smooth approach of the head to a given recording track with an error not exceeding half the track width in the search modes for the required piece of information and normal playback. The reading head, and with it the laser beam, moves across the disk field by the head motor. Engine operation is controlled by forward and reverse motion signals from the control processor, as well as signals generated by the radial error processor.

The radial tracking servo system keeps the laser beam on the track and optimal conditions reading information. The system operates based on the three light spot method. The essence of the method is to split the main laser beam using diffraction grating into three separate beams with slight divergence. The central light spot is used for reading information and for operating the autofocus system. Two side beams are located in front and behind the main beam with a slight offset to the right and left. The mismatch signal of these beams from the positioning sensors affects the tracking drive, causing, if necessary, correction of the position of the central beam.

The performance of the radial tracking system can be monitored by changes in the error signal supplied to the tracking drive.

Monitoring and control of the vertical movement of the focusing lens is carried out under the influence of servofocus. This system ensures precise focusing of the laser beam while working on the working surface of the disk. After loading and starting the CD, focus adjustment begins based on the maximum level of the output signal of the photodetector matrix and minimum level error signal of fine focusing detectors and zero focus passing. At the moment the disc starts, the CD-ROM control processor generates correction signals that provide multiple (double or triple) movement of the focal lens necessary to accurately focus the beam on the disc track. When focus is found, a signal is generated that allows information to be read. If after two or three attempts this signal does not appear, the control processor turns off all systems and the disk stops. Thus, the performance of the focusing system can be judged both by the characteristic movements of the focal lens at the moment the disk starts, and by the signal that starts the disk acceleration mode when the focus of the laser beam is found.

The information reading system contains a photodetector matrix and differential signal amplifiers. The normal operation of this system can be judged by the presence of high-frequency signals at its output when the disk rotates.

The laser diode control system provides the rated excitation current of the diode in the disk starting and information reading modes. A sign of normal operation of the system is the presence of an RF signal with an amplitude of about 1 V at the output of the reading system.

Systems for recording, reading and subsequent processing of information determine the general functional diagram of a CD-ROM, presented in the functional diagram. In addition to the systems discussed above, it includes a clock generator that provides clock signals to all CD-ROM nodes, and an EFM demodulator that converts 14-bit code messages from the disk into 8-bit serial code. Next, the information enters the digital data processor, which, together with the system control processor, is the heart of the entire device. This is where data deinterleaving and error correction occurs. The task of data interleaving when recording information is to “stretch” each byte of information over several recording frames. Moreover, if even a few frames of information are lost as a result of mechanical damage to the disk surface, the result of reverse data interleaving will be the presence of small errors in individual bytes. Such errors are corrected by an error correction circuit.

A digital versatile disc (DVD) is a type of storage device that, unlike CDs, was designed for wide use from the moment it entered the market.

DVD formats

There are five physical formats (or books) of DVD, which are not much different from the various "shades" of CD:

- DVD ROM is a high-capacity read-only storage medium;

- DVD video is a digital storage medium for movies;

- DVD audio - for audio storage only; audio CD-like format;

- DVD R - write once, read many times; format similar to CD-R;

- DVD RAM is a rewritable (erasable) version of DVD, which was the first to appear on the market and subsequently found DVD RW and DVD+RW formats as competitors.

Having the same size as a standard CD (diameter 120 millimeters, thickness 1.2 millimeters), DVDs provide up to 17 GB of storage with transfer speeds faster than CD-ROMs, access times similar to CD-ROMs, and come in four versions:

- DVD 5 - single-sided single-layer disc with a capacity of 4.7 GB;

- DVD 9 - single-sided double-layer disc 8.5 GB;

- DVD 10 - double-sided single-layer disc 9.4 GB;

- DVD 18 - holds up to 17 GB on a double-sided, double-layer disc.

In addition, there is a project for the DVD 14 format - two layers on one side, one on the other, which, being easier to produce, will replace DVD 18 until the need for the latter is fully realized.

It is important to recognize that in addition to the five physical formats, DVD also has many application formats such as DVD video and DVD audio.

DVD technology

At first glance, a DVD disc looks no different from a CD: a plastic disc 120 millimeters in diameter and 1.2 millimeters thick, both use lasers to read data written in depressions in a spiral track. However, DVD's sevenfold increase in data capacity over CD was largely achieved by pushing all the tolerances of its predecessor system.

Firstly, the tracks are placed more densely, the DVD track pitch (distance between them) is reduced to 0.74 microns, more than 2 times compared to 1.6 microns for a CD. The pits are also much smaller: the minimum pit length for a single DVD layer is 0.4 microns, compared to 0.834 microns for CDs. Overall, this gives DVD ROMs four times the storage capacity of CDs. Densely packing data is only part of the solution; DVD's main technological advance lies in its laser. Smaller pit sizes mean the laser has to illuminate a smaller area, and in DVD technology this is achieved by shortening the laser wavelength from 780 nm (infrared light for a standard CD) to 635 or 650 nm (red light).

Characteristics of the recording medium for CD (a) and DVD (b)

Secondly, the DVD specification allows information to be read from more than one layer by changing the focus of the reading laser beam. Moving from track to track of different layers requires only a moment to refocus the lens from one reflective layer of the layer to another. Instead of an opaque reflective layer, this uses a transparent layer with an opaque reflective layer behind it. While the second layer may not be as dense as the single layer, it still allows 8.5GB of data to be written to a single drive.

- a - single-sided single-layer (4.7 GB);

- b - one-sided two-layer.

Third, DVD allows you to use double-sided discs. To make it easier to focus the laser beam on smaller dimpled tracks, manufacturers used a thinner plastic backing for the disc than a CD-ROM. This reduction has resulted in disks that are 0.6 millimeters thick - half the size of a CD-ROM. However, since these discs are too thin to remain flat when processed, the manufacturers glued the two discs together, resulting in discs that are 1.2 millimeters thick. This effectively doubles the drive's potential capacity.

- a - single-sided, single-layer (4.7 GB);

- b - single-sided, double-layer (8.5 GB);

- c - double-sided, single-layer (9.4 GB);

- g - double-sided, two-layer (17 GB).

Finally, DVDs use a more efficient data structure. When CDs were developed in the late 1970s, they used relatively simple and crude error correction systems. More efficient error-correcting code for DVDs leaves more memory for actual data.

Compatibility issues

The DVD format has been plagued with compatibility issues from the very beginning. Some of these are now resolved, but others, particularly the compatibility of rewritable and video disc options, remain and look as if they are poised to grow to the scale of the Beta and VHS format war that has been going on for several years between VCR manufacturers.

Incompatibility with some CD-R and CD-RW drives has been a long-standing problem. The blanks used in some of these devices may not reflect properly laser ray, used in DVD ROM readers, which makes them “unreadable”. For CD-RW media, this problem was easily solved by the Multi-Reading standard and by equipping the DVD ROM device with lasers with two different wavelengths. However, getting DVD ROM drives to reliably read all CD-R media is a much bigger challenge. The laser of a DVD reader has difficulty reading CD-Rs due to the reduced reflectivity of the surface in light at 650 nm, while at 780 nm it is almost the same as for CD-ROMs.

By the fall of 1998, DVD ROM drives were still unable to read rewritable DVD discs. This incompatibility was finally eliminated in the so-called "third generation" drives that began appearing in mid-1999. They use a modified LSI designed to recognize different physical locations of DVD RAM data or handle additional headers in the DVD+RW data stream.

Speed was another issue for early DVD ROM drives. By mid-1997, the best CD-ROM drives used Constant Angle Velosity (CAV) to achieve higher transfer speeds and lower vibration. However, early DVD ROM devices used constant linear velocity (CLV). This was not a problem for DVDs, since their high density allows them to operate at slower rotation speeds. However, since constant line speed was also used to read CD-ROM discs, it turned out that the effective read speed of CLV DVD ROM could not be more than 8x.

The table contains aggregate information on read/write compatibility of various formats. "Yes" means that some of the devices of this type can process the corresponding disk format, it does not guarantee that all such devices will be able to do so. "No" means that the corresponding drive type can rarely or never handle the format.

Compatibility table for various DVD optical media

| DVD disc format | DVD drive type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DVD player | DVD R(G) | DVD R(A) | DVD RAM | DVD RW | DVD+RW | |||||||

| R | W | R | W | R | W | R | W | R | W | R | W | |

| DVD ROM | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No |

| DVD R(G) | Yes | No | Yes | Yes | Yes | No | Yes | No | Yes | Yes | Yes | No |

| DVD R(A) | Yes | No | Yes | No | Yes | Yes | Yes | No | Yes | No | Yes | No |

| DVD RAM | No | No | No | No | No | No | Yes | Yes | No | No | No | No |

| DVD RW | Yes | No | Yes | Yes | Yes | No | Yes | No | Yes | Yes | Yes | No |

| DVD+RW | Yes | No | Yes | Yes | Yes | No | No | No | Yes | No | Yes | Yes |

| CD-R | No | No | No | No | No | No | Yes | No | Yes | Yes | Yes | Yes |

| CD-RW | No | No | No | No | No | No | Yes | No | Yes | Yes | Yes | Yes |

Recordable DVD

DVD R (or recordable DVD) is in many ways conceptually similar to CD-R - it is a write-once medium that can contain any type of information typically stored on mass-produced DVDs - video, audio, pictures, data files, multimedia programs, and so on. Depending on the type of information being recorded, DVD R discs can be used in virtually any compatible DVD playback device, including DVD ROM drives and DVD video players. The very first DVD R played a significant role in the development of the DVD ROM market, as developers software needed a simple and relatively cheap way to create test discs before going into mass production.

DVD R discs initially had a capacity of 3.95 GB when introduced in the fall of 1997, which later increased to 4.7 GB for a single-layer, single-sided DVD R disc. Since the DVD format supports double-sided discs, up to 9.4 GB can be stored on a double-sided DVD R disc. Data can be written to DVD at 1x speed (11.08 Mbps, which is approximately equivalent to 9x CD-ROM speed). Once written, DVD R discs can be read at the same speeds as mass-produced discs, depending on the x-factor (speed factor) of the DVD ROM drive used.

The table illustrates the differences between some basic parameters of both formats.

CD-R, DVD-R format table

DVD R, like CD-R, uses Constant Linear Velocity (CLV) to maximize recording density on the disc surface. This requires a variable number of revolutions per minute (rpm) as the diameter of the track changes as it moves from one edge of the disk to the other. The recording starts on the inside and ends on the outside. At 1x, the rotation speed varies from 1623 to 632 rpm for a disk with a capacity of 3.95 GB and from 1475 to 575 rpm for 4.7 GB, depending on the position of the recording and playback head on the surface. For a 3.95 GB disk, the track spacing (feed), or the distance from the center of one turn of a spiral track to the adjacent part of the track, is 0.8 microns (microns) or half that of a CD-R. A 4.7 GB disk uses an even smaller track feed - 0.74 microns.

DVD R discs are written using a layer of material that is transformed (colored) by a highly focused red laser beam. The layer is applied to a transparent base that is injection molded polycarbonate and has a microscopic spiral groove (track) formed on its surface. This recess is used by the DVD R drive to guide the recording laser beam and also contains the recorded information after the process is completed. In addition, firstly, the spiral recess has a wavy profile (a pre-recorded sine wave) which is designed to synchronize the spindle motor of the disk during recording, and secondly, “land pre-marks” are placed in the surface areas between the recesses. Pits", or LPP), used for positioning (addressing) purposes. Next, a thin layer of metal is sprayed onto the recording layer so that the reading laser beam can be reflected from the disc during playback. A protective layer is then applied to the metal surface, along which the two sides of the disk can be glued.

These operations are performed for each side of the disk that will be used for recording. If both sides are used for recording, the two recording sides can be connected together as shown in the figure. In this case, each side must be read directly by turning the disc over. If a single-sided disc is created, the opposite side may contain a label or some other visible information.

Writing is accomplished by instantly irradiating the recording layer with a highly focused, high power laser beam (approximately 8-10 mW). When the paint layer is heated, it changes so that microscopic marks are formed in the spiral depression. These marks have a variable length depending on how long the writing laser has been on or off, which corresponds to the information stored on the disk. The recording layer is sensitive only to light of the appropriate wavelength, so exposure to ambient light or the playback laser beam cannot spoil the recording.

Reproduction is accomplished by focusing a laser beam of lower power and approximately the same wavelength (635 or 650 nm) on the surface of the disk. The surface areas between the recorded marks are highly reflective and most of the light rays are returned to the optical head of the player, and conversely, the marks themselves reflect little light. This creates a modulated signal, which is then decoded into original user data by the playback device.

By the end of 1999, DVD R adoption remained slow and drives were extremely expensive - about 10 times the cost of DVD ROM devices. Subsequently, in mid-1999, DVD ROM drives capable of reading DVD RAM disks appeared. The media's high capacity and durability (typical "lifespan" of more than 100 years) make these technologies good choice for long-term archival storage of any information that can be presented in digital form. Because the physical dimensions of DVDs are identical to the CD family, they can fit on existing mass-produced CD storage devices (“jukeboxes”). This allows automated searching of data recorded on DVD-R volumes in networked environments, while increasing storage capacity by 6-7 times compared to CD-R technology.

The introduction of Version 2 of the DVD Forum Specification in May 2000 and the subsequent increase in capacity to 4.7 GB led to the increased role of DVD R as a tool for creating master discs (matrices) before mass release of software, multimedia production and as a medium for to make copies of films. At the same time, it became clear that a different type of DVD R media was needed for the consumer market, so the format was eventually split into "DVD R for Authoring" and "DVD R for General".

The DVD R(A) format is still aimed at the professional user and other format differences relate to their relative market positioning. It is important to use the Cutting Master Format (CMF) in DVD R(A). This allows the 4.7 GB DVD R(A) media to be used as a direct replacement for DLT master tapes used in disc duplication.

A key characteristic of the DVD R(G) format (and quite possibly a major factor in the DVD Forum's decision to split the DVD R format) is that it employs content protection measures that make it physically impossible to make bit-by-bit copies of encrypted discs. special method. Secondly, DVD R(G) uses a mark-in-place (LPP) descending system, a built-in reference area, and allows the creation of double-sided discs.

Until mid-2001, DVD R's were used primarily in professional applications such as video duplication and graphic data storage. However, the prospects for wider use of the DVD R(G) format were greatly improved by the introduction of the Pioneer DVR-A03 recorder, designed to record DVD R(G), DVD RW, CD-R and CD-RW formats for around $1,000

In the fall of 2003, around the same time that DVD+ proponent Philips released dual-layer DVD+R media, pioneer announced that a version of the dual-layer DVD R format had been developed, which it intended to offer to the DVD Forum as a new disc standard after further development.

When using the color change layer recording method, the new dual-layer DVD R technology exhibits almost the same performance as dual-layer DVD ROM discs, absorbing 9.34 percent fluctuation on the first recording layer (L0) of the disc with a reflectance of 17.3% and fluctuation 8.08 percent on the second layer (L1) with a reflectance of 19.5%. This means that it will be possible to play dual-layer DVD R discs on most existing DVD players and that DVD recorders using this technology can easily be developed.

RVD-RAM

Rewritable DVD ROM or DVD RAM uses phase change technology, which is not the pure optical technology of CD and DVD, but mixed with some features of magneto-optical techniques and has its origins in PD optical disk systems (Panasonic technology). The land groove format used allows you to record signals both on the grooves formed on the disk and in the spaces between the grooves. The recesses and sector headers are formed on the surface of the disk during the casting process. The first generation of DVD RAM products with a capacity of 2.6 GB on both sides of the disc for repeated use appeared in mid-1998. However, these early devices are not compatible with higher capacity standards that use a contrast expansion layer and a thermal buffer layer to achieve higher recording densities. The specification for version 2.0 of DVD RAM with a capacity of 4.7 GB on one side was released in October 1999. Hitachi achieved a capacity of 4.7 GB by reducing the size of the laser write mark from 0.41-0.43 μm to 0.28-0.30 μm and the track feed from 0.74 to 0.59 μm.

The main difference between DVD RAM and ROM is compatibility. Single-sided DVD RAM discs are available with or without cartridges. There are two types of cartridges: type 1 - sealed, type 2 - allowing you to remove the disc. Cartridge dimensions - 124.6 x 135.5 x 8.0 millimeters. Discs can only be written while in a cartridge. Double-sided DVD RAM discs are housed in sealed cartridges and cannot be read by older DVD ROM drives. The first DVD ROM drive capable of reading DVD RAM media, sometimes informally referred to as a "third generation drive", hit the market in 1999

DVD RW

Previously known as DVD R/W or DVD ER, DVD RW media emerges from Pioneer's evolutionary development of existing CD-RW/DVD R technologies, which became available in late 1999. One of the goals was to produce a format that was compatible with existing DVD environment. In particular, DVD RW discs do not require protective cartridges, allowing them to be used with the disc loading mechanisms found in all existing players and drives.

DVD RW discs use phase change technology to read, write and erase information. The 650 nm laser beam heats the sensitive alloy layer to convert it to either a crystalline (reflective) state or an amorphous (dark, non-reflective) state, depending on the temperature level and subsequent cooling rate. The resulting difference between the recorded dark marks and the erased reflective marks is recognized by the player or disc drive and allows the stored information to be reproduced.

DVD RW media uses the same physical addressing scheme as DVD R. During recording, the drive's laser follows a microscopic groove, writing data in a spiral track. The walls of the microscopic cavity are modulated in a sinusoidal manner, producing a signal that is read by the disk drive and compared with a signal by the generator to ensure accurate rotation of the disk. This modulated pattern is called a "wobble groove" because the walls of the groove seem to oscillate from side to side. This signal is used only during recording and does not affect the playback process in any way. Among the DVD family of formats, only recordable media use modulated tracks.

The disk is created with a pre-formatted addressing scheme that uses surface marks (LPP) to identify the physical address of the data blocks being written. This design uses a series of microscopic projections that are prominent in the surface area between the indentations.

The first DVD RW home video recorder, released in Japan in late 1999, used the new DVD VR (Video Recording) format. Consequently, discs recorded on it could not be used in existing DVD players because they were compatible at the "physical layer" but not at the "application layer". The subsequent adoption of the DVD Video format resolved this specific problem, and Pioneer's DVR-A03 drive, released in 2001, provided the most comprehensive coverage of the recordable DVD R, DVD RW, CD-R and CD-RW formats.

However, despite the project's successes, many obstacles remained to making DVD RW fully compatible with existing players. For example, some drives and players mistake DVD RW for a dual-layer disc due to the media's low reflectivity and attempt unsuccessfully to locate the non-existent second layer. Therefore, some DVD ROM players are unable to play DVD RW discs.

One of the main advantages of the third rewritable DVD format, DVD+RW, is that it provides better compatibility than any of its competitors.

DVD+RW

The DVD RAM specification was a compromise between two different proposals from the main competitors - the Hitachi group, Matsushita Electric and Toshiba, on the one hand, and the Sony / Philips alliance on the other. However, there has been a constant tug-of-war since the early days of DVD, and in the summer of 1997, Sony and Philips, along with Hewlett Packard, abandoned the agreed-upon format to develop a phase-change method known as DVD+RW. The format is based on CD-RW technology, but is incompatible with the DVD RAM standard, which was agreed upon only three months earlier. Since they had no intention of withdrawing completely from the DVD Forum, the DVD+RW camp submitted a modified form of the original specification to the European Computer Manufacturers Association (ECMA) for approval as a standard. The format, however, was not supported by the DVD Forum.

Because DVD RAM media typically used shells or cartridges (resembling a size 5 floppy disk), this was particularly criticized by DVD+RW advocates, who argued that this approach would force future DVD ROM media to be housed in similar shells (cartridges). A single-sided DVD RAM disc can be removed from its enclosure to be used in any DVD ROM drive, but disc manufacturers believe that the DVD RAM disc will then not be able to write reliably. Proponents of DVD+RW further argued that housing DVD RAM in a cartridge requires a larger drive mechanism, limiting the technology's use in laptops or small computer cases. Companies aligned with the DVD Forum (Matsushita, Hitachi and Toshiba), on the other hand, argued that DVD RAM cartridges improve reliability, especially for double-sided media, and that the costs and difficulties of creating DVD ROMs physically compatible with RAM-DVDs are exaggerated .

DVD+RW shares many similarities with competing DVD RW technology in that it uses phase change media and offers the same user experience as CD-RW discs. Users can either record empty disk, or use a protective shell or cartridge. This is a major difference from DVD RAM devices, which require cartridge-based media. In the DVD+RW format, discs can be recorded in either Constant Linear Velocity (CLV) mode for sequential video recording or Constant Angular Velocity (CAV) format for direct access. Linking loss is the result of constant bit rate (CBR) recording being paused and then resumed, so that the disc ends up being incompatible with drives like DVD players or DVD ROM drives. Lossless linking is a technique developed specifically for DVD+RW that, when using Variable Bit Rate (VBR), allows video applications to pause and continue recording without causing loss. To do this, it is necessary to write an arbitrary block of data to a specific location on the disk with high accuracy (within 1 micron). For this purpose, the tracks on the disc are printed at a higher modulation frequency (wobble frequency), which provides conditions under which recording of information can be started and stopped at precisely defined positions. Together with the "no defect control" option, this feature allows DVD+RW discs to be written in a way that maximizes compatibility with existing DVD players and drives.

Initially, the phase-change recording layer of a DVD+RW disc is in a polycrystalline state. During the recording process, a focused laser beam heats selected areas of the material above the melting point (500-700 °C), so that the substance quickly turns into a liquid state. Then, with sufficiently rapid cooling, the liquid state stabilizes in the so-called “amorphous state.” If the recording layer is heated below the melting temperature but above the crystallization temperature (200 °C) for a sufficient time (longer than the minimum crystallization time), the atoms return to an ordered state, that is, polycrystalline.

The amorphous and crystalline states have different refractive indices and are therefore optically different.

In DVD+RW, the amorphous state has lower reflectivity than the crystalline state, and during the reading process this results in a signal identical to that produced by dual-layer DVD ROM discs, allowing DVD+RW discs to be read on DVD ROM drives as well as on DVD video players.

The carrier consists of an engraved floor and a carbonate base, onto which four layers are typically sprayed. The base is molded with a spiral recess (track) to control the servomotor, address information and other data. The phase-change layer is placed between dielectric layers, which remove excess heat from the recording layer. An alloy of silver, indium, serbium, tellurium (Ag-In-Sb-Te) is usually used as a phase-alternating layer. Chemical composition phase-alternating layer determines the minimum crystallization time. The structure of the disk (the thickness of the layers, their heat capacity and thermal conductivity) determines the rate of temperature decrease during recording. Precisely specifying the composition of the recording layer is important for obtaining necessary qualities records. In general, a low write beam power can be used if thin layers are present.

Perhaps the main advantage of DVD+RW over DVD W is in the area of compatibility. Its proponents claim that it is the only rewritable DVD technology that offers seamless media sharing between consumer electronics and computers and that the format is compatible with the majority of the more than 35 million DVD video players and DVD ROM drives installed before the end of 1999. A recording made by a DVD VCR onto a DVD+RW disc (4 hours of recording and playback on one side of the disc) can be played on a DVD video player in the same way as on personal computer with DVD ROM drive and MPEG-2 video decoder. In addition, DVD+RW allows you to combine digital video and digital data into a single file system, as required for recording multimedia applications.

All disk drives on the market in early 2002 used both Constant Linear Velocity (CLV) to achieve maximum speed 2.4x write speed for DVD+RW media (which corresponds to 3.32 MB/s), and constant angular speed to allow CD-ROM reading at 32x speed. Using these "x-factors", which are not very convenient in this "multi-format era", especially since there is a 9:1 ratio of actual transfer speeds between DVD and CD, we can say that the characteristics of the devices were: read speed - 8x (DVD ROM , DVD+RW), recording - 12x (CD) and rewriting - 10x (CD).

Which of the competing formats will dominate remains unclear in the long term. The addition of DVD R capabilities allows DVD RAM devices to burn mutually compatible discs. However, the use of cartridge-based rewritable media makes this format more useful for storing archival data than as an everyday device.

By early 2002, it seemed that the DVD RW format had the advantage. However, despite its proponents' claims of superior format compatibility, the fact that DVD+RW discs are less reflective than DVD R and therefore less compatible with some DVD players and DVD ROM drives is a potential handicap. The uncertainty about which of the competing formats would win the final victory is reflected in the fact that Sony is releasing a drive that supports both DVD RW and DVD+RW formats.

DVD+R

The first DVD+RW drives did not have the ability to write to DVD write-once media. However, in early 2002, Mitsubisi Kagaku Media (better known by its Verbatim brand name) became the first media manufacturer to support DVD+RW technology in both Rewritable and Write-once formats. Like previously released DVD+RW media, the new DVD+Recordable discs have been certified for 2.4x write speed (equivalent to 3.32 MB/s or CD-R performance at 22x speed).

In the spring of 2002, the second generation of DVD+RW drives began to appear, capable of processing both types of media. Philips was the first to demonstrate the ability to configure drives to new formats by patching the firmware.

In October 2003, Philips and Verbatim showed at the Ceatec exhibition (Japan, 2003) new technology Dual-layer DVD writer, which effectively doubles the recordable capacity of DVD+R discs from 4.7 to 8.5 GB while maintaining compatibility with existing DVD players and DVD ROM drives.

The dual-layer DVD+R system uses two thin organic films of paintable material separated by a spacer (filler). Heating with a concentrated laser beam irreversibly changes the physical and chemical structure of each layer so that the modified areas have optical properties different from the unaltered medium. This causes reflectance to fluctuate as the disc rotates, producing a read signal similar to that found in stamped DVD ROM discs.

The primary focus of development of this technology, which began in 2001, was to provide compatibility with the DVD ROM standard to ensure that the new dual-layer discs would be readable on commercially available DVD players. This was achieved by using a silver-containing alloy as the reflector material for the top thin film layer, which provides a reflectivity of at least 18 percent (which is consistent with dual-layer DVD ROM standards). In addition, the transparency of the upper recording layer is above 50 percent, allowing reading and writing at the lower layer. This layer has a higher light sensitivity, since the top layer absorbs and reflects part of the incident light, as well as a much higher reflectance (more than 50 percent), which provides, after passing through all layers, an effective reflectivity (on the surface of the disk), at least , at 18 percent. These high values of transparency and reflectivity are achieved by optimizing the thickness and placement of layers, track size and so on. Other parameters - amplitude and signal propagation - have also been optimized to ensure compatibility with current DVD standards.

What is DVD? 3

DVD Device Basics 3

Multiple surfaces DVD 5

Transfer speed and access time. 6

Burn to DVD 7

Video on DVD 8

DVD in action. 8

Sound on DVD 9

The official successor to DVD has been announced - Blue-ray Disk. eleven

What is DVD? After a long period of time spent on planning and development, the new format that everyone had been waiting for was released. The advent of the DVD format marked a transition to a new, more advanced level in the field of storage and use of data, sound and video. Initially, the abbreviation DVD stood for digital video disc, which is optical discs with large capacity. These disks are used to store computer programs and applications, as well as full-length films and high-quality sound. Therefore, the abbreviation DVD, which appeared a little later, was deciphered as digital versatile disc, i.e. a universal digital disk is more logical.

From the outside, DVDs look like regular CD-ROMs. However, DVD has much more possibilities. DVDs can store 26 times more data than a regular CD-ROM. Having physical dimensions and appearance Like a regular CD or CD-ROM, DVDs represent a huge leap in storage capacity over their ancestor's 650MB storage capacity. A standard single-layer, single-sided DVD disc can store 4.7GB of data. But this is not the limit - DVDs can be produced using a two-layer standard, which allows you to increase the capacity of data stored on one side to 8.5GB. In addition, DVDs can be double-sided, which increases the capacity of one disc to 17GB. Unfortunately, you'll have to buy a new device to read DVDs, but this new hardware will read your old CD-ROMs and audio CDs just as well. What does all this mean for us? The large capacity of the new drives? This means that we truly have unlimited possibilities for learning and entertainment, for watching videos with stunning digital picture and sound quality. DVD provides clearer, higher-quality images than Laser Disc (LD) and richer sound than CD. What's more, DVD gives you choice. You can choose from which angle to view a movie scene, thanks to the fact that the same scene is filmed under different angles camera position. Thanks to this, the same film can be watched, for example, with or without scenes of violence, and the plot of the same film can change in bizarre ways. And almost all of this is already on sale! Next, we'll take a closer look at the technology that offers us so many possibilities.

DVD Device Basics Like CD-ROMs, DVDs store data by using notches along spiral tracks on a reflective metal surface coated with plastic. The laser used in DVD readers slides along the tracks along notches, and the reflected beam is interpreted by the receiving device in the form of ones or zeros. The main requirement when developing DVDs was simple: to increase the storage capacity of data by placing as many notches along the tracks on the disc as possible, while the manufacturing technology should be cheap. The result of the research was the development of a higher-frequency semiconductor laser with a shorter wavelength, as a result of which it became possible to use smaller notches.  While the laser in a typical CD-ROM device has a wavelength of 780 nanometers (nm), DVD devices use a laser with a wavelength of 650-nm or 635-nm, which allows the beam to cover twice as many notches on a single track. and twice as many tracks located on one recorded surface. Other innovations include a new sector format, more robust error correction code, and improved channel modulation. Together, these improvements further increase the data recording density by one and a half times. Strict manufacturing requirements and a slightly larger recording surface were the final obstacles in the development of DVD, which is why the data capacity of the disc is limited to 4.7Gb. But it turned out that this was not the limit. To record video and audio on DVD, a very complex data compression technology called MPEG-2 is used. MPEG-2 is the next generation of standard for compression of video and audio data, providing the ability to accommodate large amounts of information in a smaller space. The MPEG compression standard was developed by the Moving Picture Experts Group (MPEG). MPEG is a standard for compressing audio and video files into a format more convenient for downloading or sending, for example over the Internet. MPEG-1 streams video and audio data at 150 kilobytes per second -- the same speed as a single-speed CD-ROM player -- and is controlled by sampling key video frames and filling only the areas that change between frames. Unfortunately, MPEG-1 provides video image quality that is lower than video transmitted using the television standard.

While the laser in a typical CD-ROM device has a wavelength of 780 nanometers (nm), DVD devices use a laser with a wavelength of 650-nm or 635-nm, which allows the beam to cover twice as many notches on a single track. and twice as many tracks located on one recorded surface. Other innovations include a new sector format, more robust error correction code, and improved channel modulation. Together, these improvements further increase the data recording density by one and a half times. Strict manufacturing requirements and a slightly larger recording surface were the final obstacles in the development of DVD, which is why the data capacity of the disc is limited to 4.7Gb. But it turned out that this was not the limit. To record video and audio on DVD, a very complex data compression technology called MPEG-2 is used. MPEG-2 is the next generation of standard for compression of video and audio data, providing the ability to accommodate large amounts of information in a smaller space. The MPEG compression standard was developed by the Moving Picture Experts Group (MPEG). MPEG is a standard for compressing audio and video files into a format more convenient for downloading or sending, for example over the Internet. MPEG-1 streams video and audio data at 150 kilobytes per second -- the same speed as a single-speed CD-ROM player -- and is controlled by sampling key video frames and filling only the areas that change between frames. Unfortunately, MPEG-1 provides video image quality that is lower than video transmitted using the television standard.

MPEG-2 compression radically changes things. More than 97% of the digital data representing a video signal is duplicated, i.e. are redundant and can be compressed without compromising image quality. The MPEG-2 algorithm analyzes the video image looking for repetitions, called redundancies. The redundancy removal process results in superior MPEG-2 video at lower bit rates. For this reason, modern video delivery media, such as digital satellite systems and DVD, use the MPEG-2 standard.

Multiple DVD Surfaces

Most DVDs have a capacity of 4.7GB. The use of density doubling schemes and their combination allows you to have larger capacity disks: from 8.5Gb and 9.4Gb to 17Gb.

The following DVD structure types exist:

Single Side/Single Layer: This is the simplest DVD disc structure. This disk can accommodate up to 4.7 GB of data. By the way, this capacity is 7 times greater than the capacity of a regular audio CD and CD-ROM disc.

Single Side/Dual Layer: This type of disc has two layers of data, one of which is translucent. Both layers are read from one side and such a disk can accommodate 8.5 GB of data, i.e. 3.5 GB more than a single-layer/single-sided disc.

Single Side/Dual Layer: This type of disc has two layers of data, one of which is translucent. Both layers are read from one side and such a disk can accommodate 8.5 GB of data, i.e. 3.5 GB more than a single-layer/single-sided disc.

Double Side/Single Layer: This drive holds 9.4 GB of data (4.7 GB on each side). It is easy to see that the capacity of such a disc is twice that of a single-sided/single-layer DVD disc. However, because the data is on both sides, you will have to flip the disk over or use a device that can read the data on both sides of the disk on its own. Double Side/Double Layer: The structure of this drive allows you to store up to 17 GB of data on it (8.5 GB on each side). Note that all figures given correspond to capacity specified in millions of bytes; if you round using a different method, taking as a basis that 1Kb = 1024 bytes, and not 1000 bytes, you will get different numbers: 4.38GB, 7.95GB, 8.75GB, and 15.9GB, respectively.

Double Side/Single Layer: This drive holds 9.4 GB of data (4.7 GB on each side). It is easy to see that the capacity of such a disc is twice that of a single-sided/single-layer DVD disc. However, because the data is on both sides, you will have to flip the disk over or use a device that can read the data on both sides of the disk on its own. Double Side/Double Layer: The structure of this drive allows you to store up to 17 GB of data on it (8.5 GB on each side). Note that all figures given correspond to capacity specified in millions of bytes; if you round using a different method, taking as a basis that 1Kb = 1024 bytes, and not 1000 bytes, you will get different numbers: 4.38GB, 7.95GB, 8.75GB, and 15.9GB, respectively.

It is easy to see that the simplest way to double the capacity is to use double-sided disks. Manufacturers can make DVDs as thin as 0.6mm, which is half the thickness of a standard CD. This makes it possible to connect two drives with opposite sides and get a capacity of 9.4Gb. Another technology creates a second layer to house data, which allows you to increase the capacity of one side of the disk. The first layer is made translucent, so the laser beam can pass through it and be reflected from the second layer. According to this scheme, 8.5GB of data can be placed on each side of the disk.

It is easy to see that the simplest way to double the capacity is to use double-sided disks. Manufacturers can make DVDs as thin as 0.6mm, which is half the thickness of a standard CD. This makes it possible to connect two drives with opposite sides and get a capacity of 9.4Gb. Another technology creates a second layer to house data, which allows you to increase the capacity of one side of the disk. The first layer is made translucent, so the laser beam can pass through it and be reflected from the second layer. According to this scheme, 8.5GB of data can be placed on each side of the disk.

How to repair a CD-DVD drive yourself?

This is a short story with pictures about how you can revive a CD-DVD, and probably a Blu-Ray drive, without resorting to the expensive help of specialists. There are several common reasons that can lead to complete or partial drive failure. Eliminating these causes is not a repair, but rather a maintenance of the CD-DVD-ROM and can easily be performed by a user who has some skills in working with electronic equipment. More details on the website

The most interesting videos on Youtube

The most common causes of drive failure.

- Worn drive belt (passenger).

- Increased friction in the loading mechanism.

- The laser lens is dirty.

- Reduced laser efficiency.

To eliminate any of these causes, partial disassembly of the drive is required. The design of the drives may vary, so the accompanying pictures should not be taken absolutely.

For preventive maintenance we will need the following tools, materials and components. website

- Paper clip.

- Phillips screwdriver.

- Medium size brush.

- Calico (cotton fabric).

- Silicone grease SI-130.

- Passik.

- Cleaning cloth.

- Thin screwdriver.

- Tweezers.

Begin. Disconnect the cables from the drive and unscrew the mounting screws. We remove the drive from the system unit case.

Disassembly.

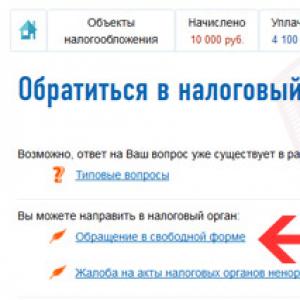

Disassembling any CD-DVD drive begins with pulling out the tray. To pull out the tray, you first need to make a simple device from a paper clip.

Carefully, by inserting the end of a paper clip into the technological hole on the front panel of the drive, we feel for the part of the mechanism that is responsible for locking the tray. This part is located exactly opposite the hole. We press on it and the tray extends slightly. Now you can pull it out with your fingers.

We release the latches securing the front panel of the drive. First, press out one of the side latches.

Then, press the latch located at the bottom of the drive and the other side latch.

Pull out the front panel, unscrew the four Phillips screws and remove the metal casing panels.

We press the latches and separate the tray from the main mechanism.

Thoroughly clean the mechanism from dust and dirt using a brush. If the old lubricant is heavily contaminated, then remove it using calico and apply new lubricant.

We replace the worn belt with a new one. Then we wipe the belt and the internal surfaces of the pulleys with a cleaning cloth or calico soaked in alcohol.

Wipe the laser lens with a cleaning cloth. Dust deposited on the top surface of the lens may not be visible to the naked eye, but it is almost always present there.

If the drive is very old or is known to have had too many discs written to it and is having a read or write problem, you can try increasing the laser current. This rather delicate operation requires patience and can take quite a long time. Do not attempt this procedure if your drive simply does not read several old discs or discs recorded on other people's drives. This may be caused by a mass various reasons and the laser current value is in 38th place here.

It is best to regulate the laser current when the drive is in a semi-assembled state.

To start the drive without a casing and front panel, you will have to remove the front wall of the disk tray.

Somewhere on the carriage with the laser installed there is a small-sized potentiometer, the position of the slider of which determines the laser current. The location of this potentiometer depends on the drive design.

Before turning this screw, be sure to sketch the position of the slot in order to have a reference point, and in general, so that if something happens, you can return it to its original position.

By turning the screw 10-15 degrees, first in one direction and then in the other, each time we check the reading quality in some program, for example, Nero DiscSpeed.

It is only advisable to check on several types of media at once, for example, CD-R and CD-RW or DVD+R, DVD+RW, DVD-R, DVD-RW, etc. It's probably not necessary to check all supported media types, but at least check the ones you use all the time.

Multi-purpose universal drives are quite a compromise product and therefore they often read some types of disks better and others worse. For example, by increasing the laser current, you can get perfect CD-R reading and make half of your CD-RWs unreadable.

Assembly does not present any difficulties, except for one thing. When inserting the tray into the loading mechanism, you need to align the loading mechanism slide lock with the guide groove located at the bottom of the tray.

The slide is usually spring-loaded, so before inserting the tray into the guides, you need to fix the slide in the correct position using tweezers or another suitable tool. In the photo, the position of the slider is fixed using an awl.

How to choose the right belt for repairing a CD-DVD drive.

If, quite by chance, you happen to have a small set of belts of different diameters at your disposal, then you just need to choose a suitable copy. If you don’t have such a set, you’ll have to buy a belt.

And although the era of video and audio tape recorders has passed, you can still buy an assortment of rubber belts at all kinds of radio markets.

When buying a belt, you need to pay attention to several of its parameters, such as: cross-section, diameter, elasticity and quality of vulcanization of the rubber from which it is made.

The cross-section of the belt can also be determined by eye, since the likelihood that you will be able to find a belt with a strictly appropriate cross-section is small.

The diameter of the belt can be determined by applying the old belt to the new one and making sure that the diameter of the new one is slightly smaller than the old one.

Elasticity can be measured using a makeshift stand, like the one in the picture.

I usually check the properties of the belt by touch without any dynamometers.

The quality of rubber vulcanization can be determined by color and tactile sensations. The color of the “wrong” rubber is deep black, and the surface is smooth and highly reflective. While “correct” rubber has a slightly grayish tint and a more matte surface.

Also, the quality of rubber vulcanization can be determined by the time it takes to restore the original size. To test, you need to strongly stretch the belt with your fingers and very quickly throw it flat onto a flat surface. The faster the belt takes on its original size, the higher its quality. If you can notice by eye how the diameter of the belt changes, that is, it seems to shrink, then such a belt will not last long and it is better not to use it at all. However, it is not a fact that you will find a high-quality belt at the market, and even exactly the same one as required. Therefore, in the absence of anything better, you can buy what you have, but adjusted for diameter, cross-section and elasticity.

And so, all these four parameters affect the properties of the belt. When choosing a belt, you need to take them all into account. If the cross section of the belt is slightly smaller, then you need to choose a belt that is a little shorter and vice versa. If the quality of vulcanization is low, then you need to choose either a slightly larger cross-section or a slightly smaller diameter.

If the belt is pulled too tight, it can lead to jamming or premature wear of the disk loading mechanism. If the belt is tensioned too loosely, this may cause it to slip relative to the engine pulley.

If there are several belts with similar properties at the market, then it is better to buy several different ones at once so that you can choose the most suitable one at home. The price of a belt for a CD-DVD drive can range from $0.3 to $0.7.